Top Industrial Panel Trends to Watch in 2025 for Optimal Efficiency

As we look towards the future of manufacturing, the role of industrial panels is becoming increasingly crucial in driving efficiency and innovation. Experts in the field are predicting transformative changes that will shape the landscape of industrial operations in 2025. According to Dr. Emily Zhang, a leading authority on industrial automation, "The advancements in industrial panel technology will not only enhance operational efficiency but also redefine the way industries approach sustainability."

In the upcoming years, we can expect to see a variety of trends influencing the industrial panel sector. The integration of smart technologies, such as IoT and AI, will become more prevalent, offering unprecedented data analytics capabilities to optimize performance. Moreover, the push for sustainable practices will drive the development of eco-friendly materials and energy-efficient designs, ensuring that industrial panels contribute positively to the environment.

Additionally, the demand for versatility and customization in industrial panel solutions will continue to rise. As industries evolve, the need for adaptive and scalable systems will be paramount. Understanding these trends will be essential for businesses to remain competitive, as the right industrial panel can make all the difference in achieving optimal efficiency and maintaining robust operational standards.

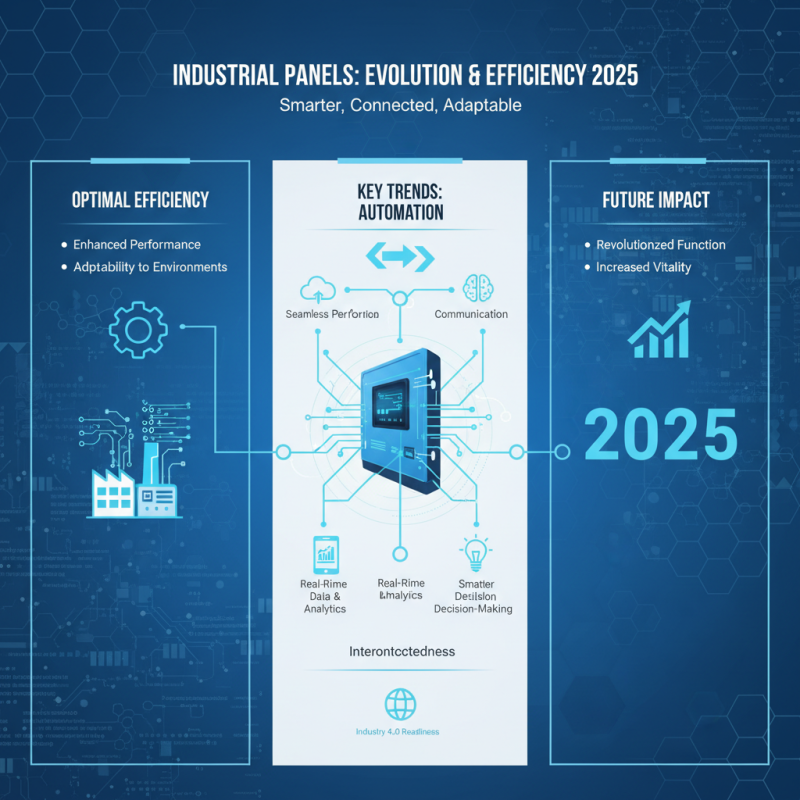

Emerging Technologies Revolutionizing Industrial Panels by 2025

As industries evolve, the role of industrial panels is becoming increasingly vital in achieving optimal operational efficiency. By 2025, emerging technologies are set to revolutionize the way these panels function, enhancing not only their performance but also their adaptability to various industrial environments. One of the central trends is the integration of advanced automation, allowing panels to communicate seamlessly with other systems and devices. This interconnectedness will enable real-time data collection and analytics, driving smarter decision-making processes.

Moreover, the adoption of artificial intelligence (AI) within industrial panels promises to elevate their capabilities significantly. AI algorithms will facilitate predictive maintenance, reducing downtime and extending the lifespan of equipment. By analyzing historical data and identifying patterns, these intelligent systems can foresee potential failures and provide actionable insights. Additionally, advancements in materials science will introduce lighter yet more durable panels, capable of withstanding harsher conditions while maintaining high functional standards. Together, these trends will not only boost operational efficiency but also pave the way for a more intelligent and responsive industrial landscape by 2025.

Advancements in IoT Integration for Enhanced Operational Efficiency

As we move towards 2025, the integration of the Internet of Things (IoT) within industrial panels stands to revolutionize operational efficiency across various sectors. The ability to connect and communicate with an array of devices enables real-time data acquisition and analysis, allowing organizations to monitor processes, reduce downtime, and enhance decision-making capabilities. Implementing IoT solutions in industrial panels facilitates seamless communication between machinery and management systems, leading to a more streamlined workflow.

Moreover, the advancements in IoT integration not only optimize productivity but also improve the maintenance and longevity of industrial equipment. Predictive maintenance, powered by IoT sensors and analytics, enables organizations to anticipate failures before they occur, minimizing the risk of unexpected downtime and associated costs. Additionally, the increased visibility into operational processes helps manufacturers respond quickly to changes in demand, ensuring that resources are utilized efficiently and waste is minimized. As these technologies continue to evolve, they empower businesses to adopt a more proactive approach to operational management, ultimately enhancing their competitiveness in a rapidly changing market.

Top Industrial Panel Trends to Watch in 2025 for Optimal Efficiency - Advancements in IoT Integration for Enhanced Operational Efficiency

| Trend | Description | Impact on Efficiency | Expected Adoption Rate by 2025 |

|---|---|---|---|

| Advanced IoT Integration | Seamless connectivity between industrial devices for real-time data analysis. | Increased operational visibility and quicker decision-making. | 78% |

| Predictive Maintenance | Using data analytics to predict equipment failures before they occur. | Reduced downtime and maintenance costs. | 65% |

| Edge Computing | Processing data closer to the source to enhance response times. | Improved efficiency in data handling and reduced latency. | 70% |

| Enhanced Cybersecurity Measures | Implementing robust security protocols to protect industrial networks. | Increased trust and reliability of operational systems. | 60% |

| Integration of AI and ML | Using artificial intelligence for smarter automation and workflow optimization. | Higher productivity through optimized processes. | 75% |

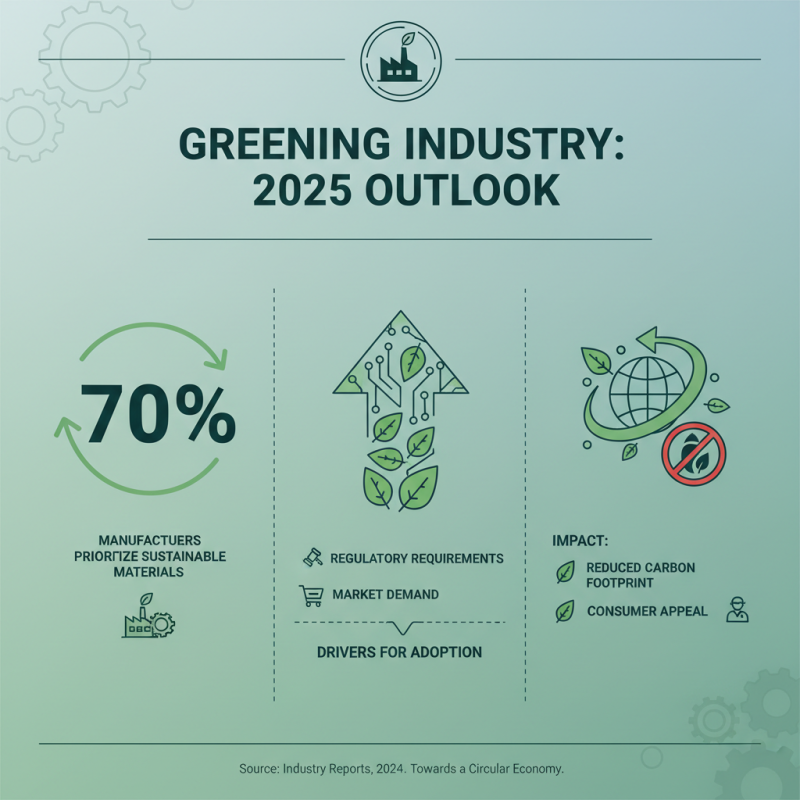

Sustainability Trends: Eco-Friendly Materials in Panel Manufacturing

As sustainability takes center stage in industrial manufacturing, the use of eco-friendly materials in panel production is becoming increasingly important. In 2025, we can anticipate a significant shift towards sustainable practices, driven by both regulatory requirements and market demand. According to recent industry reports, approximately 70% of manufacturers are expected to prioritize the integration of sustainable materials into their operations, reflecting a broader commitment to environmental stewardship. This trend not only helps reduce the carbon footprint of production processes but also appeals to consumers who are increasingly seeking out green solutions.

When considering eco-friendly materials, recycled metals and bio-based composites are leading options. These materials not only minimize dependency on virgin resources but also offer comparable, if not superior, performance to traditional panel materials. A study by the Sustainable Manufacturing Initiative noted that the use of recycled content in panels can reduce greenhouse gas emissions by up to 30% compared to conventional manufacturing methods. As industries adapt, it will be crucial to stay informed about advancements in sustainable material technology and their benefits.

Tips: As a manufacturer looking to enhance sustainability, consider conducting a lifecycle assessment of your materials. This will provide insight into their environmental impact and help identify opportunities for improvement. Also, partnering with suppliers who focus on sustainable practices can enhance your brand's credibility and commitment to eco-friendly solutions. Remember, investing in sustainable materials is not just about compliance; it’s a strategic approach to remain competitive in an evolving market.

Data-Driven Decision Making: AI and Machine Learning Applications

The integration of artificial intelligence (AI) and machine learning into industrial panel systems is revolutionizing decision-making processes across various sectors. By harnessing the power of data analytics, organizations can gain actionable insights that drive greater operational efficiency. AI algorithms can swiftly analyze vast amounts of data generated from production lines, equipment sensors, and workforce activities. This real-time analysis enables managers to identify inefficiencies, predict equipment failures, and optimize resource allocation, ultimately enhancing overall productivity.

Moreover, the advent of machine learning models allows for continuous improvement in industrial processes. These systems learn from historical data and adjust their algorithms to improve decision-making accuracy over time. For instance, they can evaluate patterns related to maintenance schedules, monitor performance metrics, and even automate routine adjustments to machinery based on predictive analytics. By minimizing human error and enabling more precise control, companies can not only streamline operations but also significantly reduce downtime and operational costs. As industries continue to embrace these technologies, the reliance on data-driven decision-making will undoubtedly become a cornerstone of efficient industrial management in 2025 and beyond.

Safety Standards and Compliance Innovations Shaping the Industry

In 2025, the industrial panel sector is expected to experience notable advancements in safety standards and compliance innovations, driven by the increasing demand for efficiency and sustainability. According to a report by the International Electrotechnical Commission (IEC), approximately 30% of industrial accidents can be traced back to inadequate safety measures in panel design and operation. As a response, industry stakeholders are prioritizing the integration of enhanced safety protocols, including real-time monitoring systems that leverage IoT technology to detect anomalies and potential hazards faster than ever.

Furthermore, compliance with evolving regulations is becoming critical for companies aiming to maintain operational integrity. The Occupational Safety and Health Administration (OSHA) has projected that compliance failures could cost the industry billions in fines and lost productivity. Innovations such as digital compliance management tools are on the rise, allowing manufacturers to streamline adherence to safety regulations and track their performance against industry benchmarks. By investing in these technologies, companies can not only mitigate risks but also improve their overall efficiency, leading to better economic outcomes as highlighted in a recent report by the National Safety Council (NSC) indicating that organizations with robust safety programs experience a 20% reduction in workplace incidents. As the industry moves towards 2025, the convergence of safety standards and compliance innovations will undoubtedly redefine the landscape of industrial panels, ensuring a safer and more efficient operational environment.

Top Industrial Panel Trends to Watch in 2025

Related Posts

-

Essential Techniques for Maximizing Industrial Panel Performance in Your Operations

-

How to Choose the Right Rugged Panel Computer for Your Toughest Environments

-

Innovative Applications of Rugged PCs in Extreme Environments

-

Exploring the Future: Top 5 Use Cases for Rugged Panel Computers in Extreme Environments

-

Revolutionizing Efficiency with Industrial Portable Computers in Manufacturing and Logistics

-

10 Essential Reasons Why Your Business Needs an Industrial Rugged PC Today