Top 10 Tips for Choosing the Best Industrial Panel PC for Your Business

Choosing the right industrial panel PC for your business is a critical decision that can significantly impact your operational efficiency and productivity. In today’s fast-paced industrial landscape, these specialized computers are essential for controlling processes, monitoring systems, and facilitating communication between machinery. With a wide variety of options available, selecting the best industrial panel PC tailored to your specific needs requires careful consideration of several factors.

In this guide, we’ll present you with the top 10 tips to help streamline your choice, ensuring that the industrial panel PC you choose meets your requirements and supports your business goals. From understanding the technical specifications to evaluating the design and usability, making an informed decision can pave the way for enhanced performance and reliability in your operations. By following these key insights, you’ll be better equipped to navigate the complex market of industrial panel PCs and ultimately select a solution that drives success for your organization.

Understanding the Specific Needs of Your Business for Panel PCs

When considering industrial panel PCs for your business, it’s crucial to understand your specific operational needs and environment. The right panel PC can enhance productivity, reduce downtime, and improve overall operational efficiency. Therefore, the initial step is to conduct a thorough assessment of your working environment—whether it's a factory floor, a warehouse, or an assembly line. This evaluation will help you identify features such as display size, durability requirements, and processing power that align with your workflows.

Tip one: Evaluate the environmental conditions where the panel PC will be used. For instance, if the panels are to be installed in areas with high levels of dust or moisture, selecting devices with appropriate IP ratings can safeguard against potential damage. Tip two: Consider scalability and compatibility. As your business evolves, your technological needs might change. Therefore, choosing a panel PC that can seamlessly integrate with your existing systems and is future-proof will save time and resources in the long run.

Furthermore, Tip three: Focus on user interface and ergonomics. A user-friendly interface can significantly reduce training time for employees, while a design that considers operator comfort can enhance usability over extended periods. By concentrating on these specific requirements, you can ensure that the industrial panel PC you select not only meets current demands but also supports future growth.

Top 10 Considerations for Selecting an Industrial Panel PC

Evaluating the Technical Specifications of Industrial Panel PCs

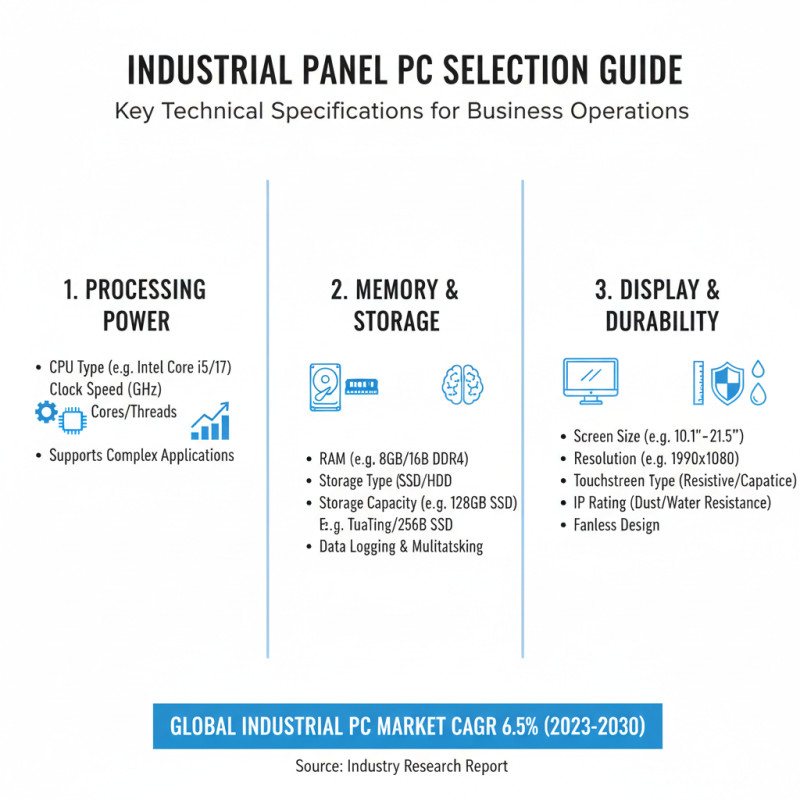

When selecting an industrial panel PC, evaluating the technical specifications is crucial to ensure it meets the operational demands of your business. Panel PCs vary widely in terms of processing power, memory, and display size, so it is essential to align these specifications with the specific needs of your application. For instance, a report from Industry Research indicates that the global industrial PC market is expected to grow at a CAGR of 6.5%, highlighting the increasing reliance on sophisticated hardware that can support complex applications in manufacturing and automation.

One of the critical specifications to examine is the processing unit. Industrial panel PCs commonly feature Intel® or ARM-based processors, with a growing trend favoring multi-core configurations that can handle multitasking efficiently. Memory is another vital aspect; a system with at least 4GB of RAM is advisable for general applications, while resource-intensive tasks may require 8GB or more. Additionally, consider the display resolution and touchscreen responsiveness, as these can significantly impact user interaction and productivity. Recent surveys indicate that over 70% of operators prefer touch interfaces for ease of use in dynamic environments, affirming the importance of selecting a model with the right technical attributes tailored to the user experience.

Robustness and durability specifications should not be overlooked either. Industrial panel PCs need to withstand harsh conditions, so factors such as IP ratings for dust and water resistance, as well as operating temperature ranges, are essential. According to research by MarketsandMarkets, products with higher durability standards can lead to a decrease in maintenance costs by up to 30%, highlighting the long-term benefits of investing in quality equipment. Ensuring these technical specifications align with your operational environment will ultimately lead to enhanced productivity and reliability in industrial settings.

Assessing the Environmental and Durability Requirements

When selecting an industrial panel PC for your business, assessing environmental and durability requirements is critical to ensure the longevity and performance of the device in demanding settings. Industrial panel PCs often operate in harsh environments where temperature fluctuations, dust, moisture, and vibrations are the norm. According to a report by Research and Markets, the global industrial PC market is expected to reach $5.31 billion by 2025, which highlights the growing need for robust computing solutions that can withstand such conditions.

Key factors to consider include the ingress protection (IP) rating, which specifies the device's resistance to solids and liquids. A minimum IP rating of IP65 is recommended for environments with significant dust and washdown requirements. Additionally, temperature tolerance should align with your operational conditions; many industrial panel PCs can operate within a broad range of temperatures, often from -20°C to 60°C. It is also important to evaluate the use of durable materials, such as industrial-grade aluminum or stainless steel enclosures, which enhance resistance against corrosion and physical impacts. Comprehensive testing for compliance with industrial standards (like IEC 60068 for environmental testing) is crucial for ensuring that chosen devices can handle the rigors of their operational environments without compromising on performance.

Top 10 Tips for Choosing the Best Industrial Panel PC for Your Business

| Criteria | Requirement/Recommendation | Importance Level |

|---|---|---|

| Operating Temperature Range | -20°C to 60°C | High |

| Ingress Protection Rating | IP65 or above | High |

| Vibration Resistance | 5-500 Hz, 2G | Medium |

| Shock Resistance | 15G | Medium |

| Power Supply | Wide input range (AC/DC) | High |

| Display Size | 10" to 21" | Medium |

| CPU Performance | Industrial-grade processors | High |

| Networking Capabilities | Ethernet, Wi-Fi, Serial ports | Medium |

| Mounting Options | Wall, Panel, VESA | Low |

| Warranty Period | 3 years minimum | High |

Comparing Features: Touchscreens, Connectivity, and Performance

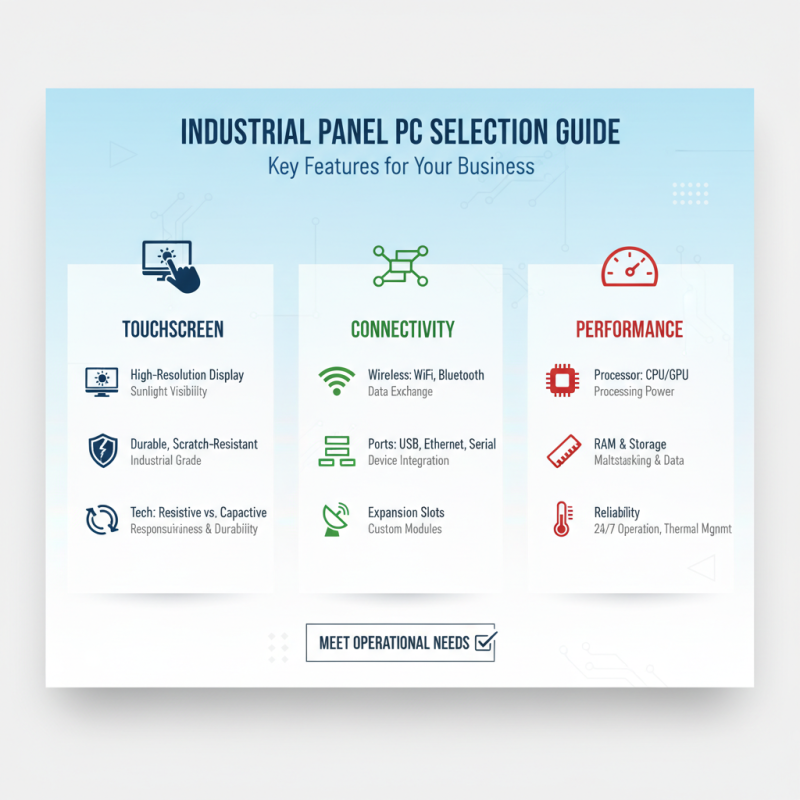

When selecting the best industrial panel PC for your business, it's essential to focus on features such as touchscreens, connectivity, and performance to ensure that the system meets your operational needs. Touchscreens have become increasingly popular in industrial settings due to their intuitive usability. Look for models that offer high-resolution displays with good sunlight visibility and durable, scratch-resistant surfaces. Additionally, consider the touchscreen technology—resistive versus capacitive—based on your specific usage environment, as each has its advantages in terms of responsiveness and durability.

Connectivity is another critical factor to evaluate. A robust industrial panel PC should support multiple connectivity options, such as USB, Ethernet, and wireless technologies like Wi-Fi and Bluetooth. This versatility ensures seamless integration with various devices and networks, facilitating efficient data transfer and communication within your operations. Furthermore, assess the performance capabilities, including processing power and memory, as these will directly impact the system’s ability to handle demanding applications and multitasking requirements typical in industrial workflows. By carefully assessing these features, you can choose a panel PC that not only meets your current needs but also adapts to the future demands of your business.

Budget Considerations: Cost vs. Value in Panel PC Selection

When selecting an industrial panel PC, it is crucial to consider the balance between cost and value. A lower-priced option may initially seem appealing, but it’s important to evaluate the long-term implications of such choices. Factors such as durability, performance, and support services can significantly affect operational efficiency. Investing in a higher quality panel PC that offers better reliability may lead to reduced downtime and lower maintenance costs over time, ultimately providing greater value for your business.

Additionally, businesses should assess their specific needs and usage scenarios when considering their budget. The right panel PC should align with both current operational requirements and future scalability. Evaluating features such as processing power, display quality, and environmental resilience can help ensure that the selected unit not only meets today's demands but can also adapt to future advancements without necessitating a complete overhaul. Thus, understanding the trade-offs between upfront costs and potential long-term savings is essential for making an informed decision that aligns with both financial constraints and operational objectives.

Related Posts

-

10 Unique Industrial Panel PC Solutions for Buyers Worldwide

-

5 Essential Tips for Choosing the Right Industrial Panel PC for Your Business

-

Mastering the Industrial Panel PC Revolution for Optimal Manufacturing Efficiency

-

How to Choose the Right Military Panel PC for Your Operations

-

How to Choose the Right Military Panel PC for Your Operational Needs

-

What is an Industrial Panel PC and How Does It Work