Why Rugged Industrial Computers Are Essential for Manufacturing Success?

In the fast-paced world of manufacturing, operational efficiency and reliability are paramount. As industries face increasing demands for productivity and technological integration, the role of rugged industrial computers becomes more critical. These specialized systems are designed to withstand harsh conditions, including extreme temperatures, vibrations, and dust, which are common in manufacturing environments. Their durability and performance not only enhance productivity but also ensure that critical processes run smoothly without the frequent interruptions caused by equipment failure.

The necessity for rugged industrial computers stems from their ability to provide consistent performance in settings where traditional computing devices often falter. Manufacturers are leveraging these robust machines to support various applications, ranging from real-time data processing to equipment monitoring and control. As the industry embraces Industry 4.0 and the Internet of Things (IoT), the demand for reliable and resilient computing solutions continues to rise, highlighting the importance of investing in rugged industrial computers for sustainable operational success.

Ultimately, as businesses seek to navigate the complexities of modern manufacturing, the integration of rugged industrial computers not only enhances productivity but also contributes to overall safety and reliability in the workplace. By ensuring that systems can perform under adverse conditions, companies can maintain competitiveness and drive growth in an ever-evolving landscape.

Importance of Rugged Industrial Computers in Manufacturing Settings

In the fast-paced world of manufacturing, the reliance on rugged industrial computers has become paramount. These systems are specifically designed to withstand the harsh conditions often found in factory settings, including extreme temperatures, dust, and vibrations. According to a report by the International Data Corporation (IDC), over 50% of manufacturers have reported productivity losses due to equipment failures caused by inadequate computing solutions. The durability and reliability of rugged industrial computers not only enhance operational efficiency but also significantly reduce downtime, saving valuable resources.

Tips: When selecting rugged industrial computers, consider those with certifications such as IP65 or MIL-STD-810, which indicate resistance to dust and moisture. Additionally, ensure the devices are equipped with advanced thermal management systems to operate effectively in high-temperature environments.

Furthermore, the integration of rugged industrial computers into manufacturing operations can boost data collection and processing efficiency. A study from the Manufacturing Institute found that manufacturers utilizing robust computing technologies saw a 20% increase in data accuracy and availability. This improvement allows for real-time monitoring and analytics, enabling companies to make swift decisions based on reliable information, ultimately improving productivity and competitiveness in the market.

Tips: Don't overlook the importance of software compatibility when implementing rugged systems. Ensure that the chosen industrial computer can seamlessly operate the necessary applications to maximize performance and usability in your manufacturing processes.

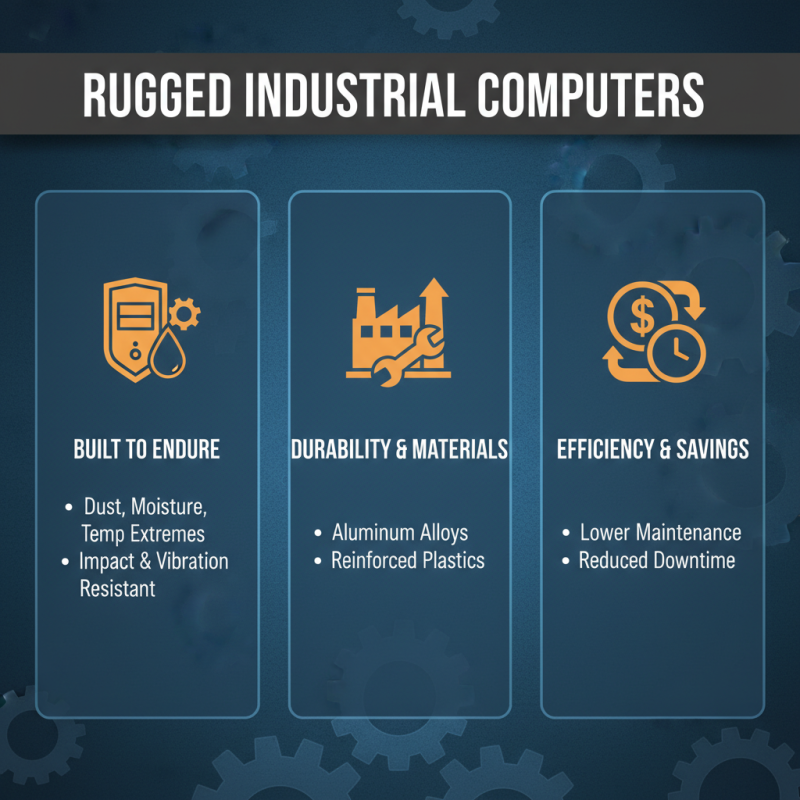

Key Features of Rugged Industrial Computers for Harsh Environments

Rugged industrial computers are specifically designed to endure the harsh conditions often found in manufacturing environments. These machines feature robust casings that protect sensitive components from dust, moisture, and extreme temperatures. With a focus on durability, many rugged models are constructed from materials such as aluminum alloys or reinforced plastics, ensuring they can withstand impact and vibration typically present on factory floors. This resilience results in lower maintenance costs and reduces the frequency of equipment failures, which can be detrimental to production efficiency.

In addition to their physical toughness, rugged industrial computers are equipped with advanced cooling systems to prevent overheating and have high ingress protection (IP) ratings, allowing them to operate safely in wet or dirty conditions. They also often include enterprise-grade connectivity options—such as multiple USB ports, serial interfaces, and wireless capabilities—to facilitate seamless communication between machines and the wider manufacturing ecosystem. These features collectively enhance operational efficiency, minimizing downtime and allowing manufacturers to maintain rigorous production schedules without compromising on quality or performance.

Benefits of Using Rugged Computers for Enhanced Operational Efficiency

Rugged industrial computers have become a pivotal asset for manufacturing operations, primarily due to their unique design tailored for challenging environments. One of the key benefits of using such computers is their ability to withstand extreme temperatures, dust, moisture, and vibrations, which are commonplace in factories. This resilient nature significantly reduces downtime caused by equipment failure, allowing manufacturing processes to run smoothly and without interruption. By minimizing the potential for technical glitches, organizations can ensure their production lines remain efficient and productive.

Moreover, rugged computers offer enhanced operational efficiency through advanced connectivity and real-time data processing capabilities. These systems are often equipped with powerful processors and ample memory, enabling them to handle complex tasks and large volumes of data swiftly. This capability is crucial when monitoring equipment performance, managing inventory, or integrating with various applications across the manufacturing floor. As a result, teams can make informed decisions quickly, respond to issues proactively, and optimize processes to achieve better overall productivity. The adoption of rugged industrial computers ultimately fosters a more resilient and responsive manufacturing environment, driving success in the competitive landscape.

Benefits of Using Rugged Industrial Computers in Manufacturing

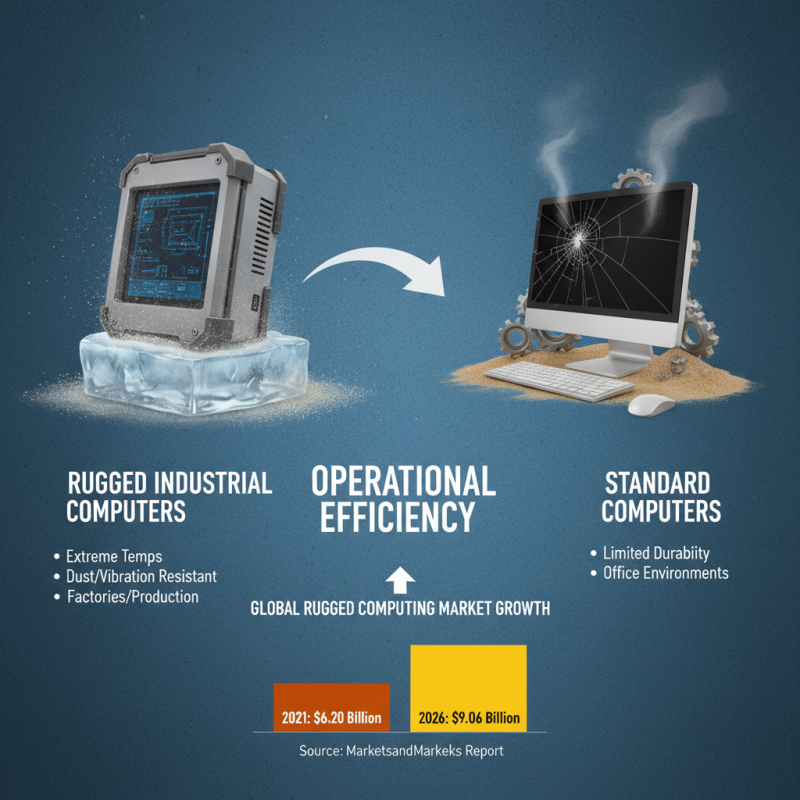

Comparative Analysis: Rugged Computers vs. Standard Computers in Industry

In the fast-paced world of manufacturing, the choice between rugged industrial computers and standard computers can significantly impact operational efficiency. Rugged computers are designed to withstand harsh environments, including extreme temperatures, dust, and vibrations, which are commonly found in factories and production floors. According to a report by MarketsandMarkets, the global rugged computing market is expected to grow from $6.20 billion in 2021 to $9.06 billion by 2026, reflecting the increasing demand for reliable technology in challenging industrial settings.

In contrast, standard computers often struggle under such conditions, leading to downtime and potential data loss. A study by Aberdeen Group highlights that companies using rugged computers experienced a 38% reduction in operational downtime compared to those relying on conventional systems. This durability not only minimizes disruptions but also extends the lifespan of technological investments, making rugged computers a more cost-effective choice over time.

**Tip:** When choosing between rugged and standard computers, assess your operational environment thoroughly. Consider factors like exposure to moisture, temperature extremes, and the likelihood of mechanical shocks.

In addition, it's crucial to evaluate the total cost of ownership. While rugged computers may have a higher initial price tag, their ability to reduce maintenance costs and enhance productivity often leads to long-term savings. Investing in technology that aligns with industrial needs can foster greater manufacturing success.

**Tip:** Ensure that the rugged computers you select come with appropriate certifications for your specific industry, such as IP ratings for dust and water resistance or MIL-STD ratings for shock and vibration resilience.

Future Trends in Rugged Industrial Computing for Manufacturing Success

As manufacturing continues to evolve in the era of Industry 4.0, the integration of rugged industrial computers becomes increasingly pivotal. According to a recent report by Grand View Research, the global rugged computing market is projected to reach $6.09 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.9%. This growth is largely driven by the increasing demand for durable, reliable computing solutions that can withstand harsh industrial environments while maintaining high performance and connectivity.

Future trends in rugged industrial computing reflect a significant shift toward enhanced connectivity and smart technologies. The Industrial Internet of Things (IIoT) is enabling real-time data analytics, leading to predictive maintenance and optimized production processes. Research from MarketsandMarkets suggests that the IIoT market is expected to grow to $110.6 billion by 2025, emphasizing the necessity for rugged computers that can support vital data collection and analysis in real time. Furthermore, advancements in artificial intelligence and machine learning are being integrated into rugged devices to streamline operations and reduce human error, heralding a transformative era for manufacturing efficiency and productivity.

Why Rugged Industrial Computers Are Essential for Manufacturing Success

| Feature | Importance in Manufacturing | Future Trends |

|---|---|---|

| Durability | Withstands harsh environments, reducing downtime. | Increasing use of advanced materials for enhanced resilience. |

| Performance | Supports high-speed data processing for real-time analytics. | Integration of AI and machine learning for predictive maintenance. |

| Connectivity | Enables seamless data transfer and remote monitoring. | Adoption of 5G technology for faster communication. |

| Energy Efficiency | Reduces operational costs and environmental impact. | Development of energy-harvesting technologies. |

| Security | Protects sensitive data and systems from cyber threats. | Enhanced cybersecurity measures integrated at the hardware level. |

Related Posts

-

Exploring the Power and Durability of Rugged Industrial Computers in Harsh Environments

-

10 Reasons Why Industrial Computing Products are the Best Choice for Your Business

-

The Future of Ruggedized Computers in Extreme Environments and Industries

-

Top 10 Tips for Choosing the Best Industrial Panel PC for Your Business

-

Exploring the Advantages of Rugged Industrial Computers in Extreme Environments: Data-Driven Insights

-

Essential Techniques for Maximizing Industrial Panel Performance in Your Operations