Top Industrial Panel PC Features and Benefits You Should Know?

In the realm of automation, industrial panel PCs play a pivotal role. Renowned expert Dr. Emily Carter states, "The evolution of industrial panel PCs has transformed operational efficiency." This statement highlights their importance in various sectors.

Industrial panel PCs combine computing power with durability. They are designed to withstand harsh environments while delivering reliable performance. These devices seamlessly integrate with machinery and control systems, enhancing productivity. For instance, factories use them for real-time monitoring, data analysis, and user interface control.

However, selecting the right industrial panel PC can be challenging. Users must consider specifications like processing power, screen size, and connectivity options. Many buyers overlook the importance of ruggedness and display quality. It’s crucial to evaluate these features carefully to ensure long-term reliability.

Top Industrial Panel PC Features: Display Quality and Resolutions

When selecting an industrial panel PC, display quality is crucial. High-resolution screens enhance clarity and detail. Look for options that support full HD or higher. Brightness is also important. A bright display ensures visibility in various lighting conditions.

Consider the touch technology too. Capacitive touchscreens respond quickly. They also support multi-touch gestures. This can improve user experience significantly. Resistive screens may be less responsive but are more durable. They work well in tough environments.

Tips: Check the screen's viewing angle. A wide angle ensures visibility from different positions. Test touch responsiveness before purchasing. Consider how the display will be used daily. Will it face dust, moisture, or direct sunlight? These factors impact durability and performance. Failure to consider these can lead to dissatisfaction later. Choose wisely.

Top Industrial Panel PC Features: Display Quality and Resolutions

Performance Metrics: Processing Power and Memory Specifications

When selecting an industrial panel PC, processing power and memory are critical metrics. Strong processing power ensures smooth operations. It allows the device to handle multiple tasks without lag. High-performance CPUs can impact overall system responsiveness. They help in managing complex applications and real-time data processing. Many users overlook the need for powerful components.

Memory specifications play an equally important role. Sufficient RAM facilitates better multitasking. It helps in running software efficiently and loading applications faster. When memory is limited, performance can suffer. Sometimes, users are surprised by slow response times. They expect higher performance from basic setups. This mismatch can lead to frustration.

Storage options also matter. Solid-state drives (SSDs) offer quicker data access. They enhance system performance significantly. However, they can be pricier than traditional drives. Users must weigh cost versus performance. Ensuring optimal specifications requires careful consideration. An unbalanced setup might not meet industrial needs.

Top Industrial Panel PC Features and Benefits You Should Know?

| Feature | Description | Performance Metric | Typical Value |

|---|---|---|---|

| Processor Type | The type of CPU used, affecting speed and efficiency | Processing Power | Dual-core / Quad-core |

| RAM Capacity | Amount of memory available for applications | Memory Specification | 4GB / 8GB / 16GB |

| Storage Type | The technology used for data storage | Data Transfer Rate | SSD / HDD |

| Screen Size | Physical size of the display unit | Display Area | 10.1" / 15.6" / 21.5" |

| Operating System | The software platform on which applications run | Compatibility | Windows / Linux |

| Environmental Rating | Durability under harsh conditions | Ingress Protection | IP65 / IP67 |

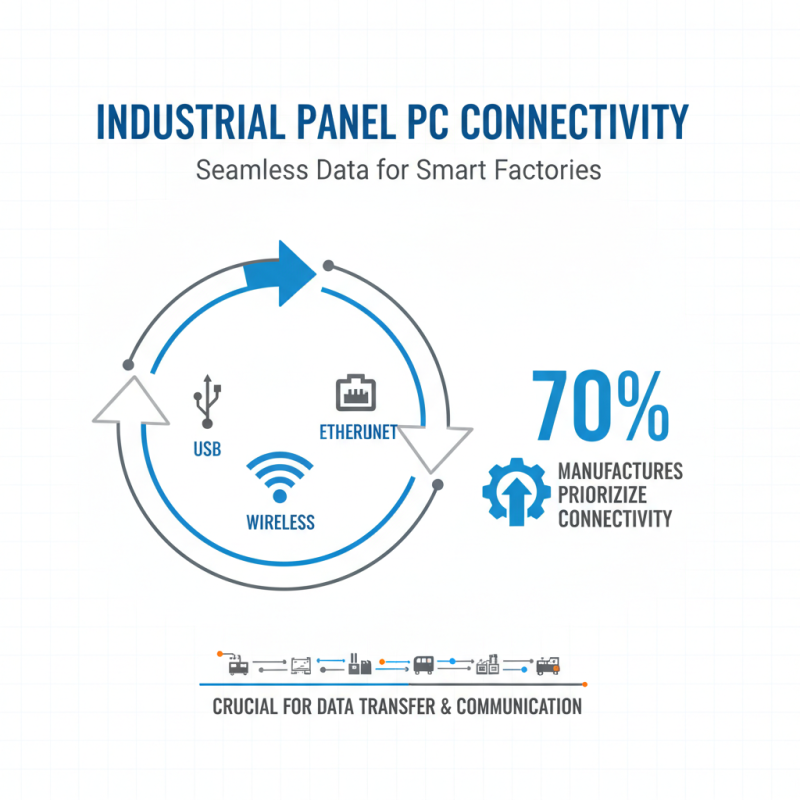

Connectivity Options: USB, Ethernet, and Wireless Technologies

Connectivity is crucial for industrial panel PCs. USB, Ethernet, and wireless technologies are key components. According to a recent industry report, 70% of manufacturers prioritize connectivity in their equipment. This trend reflects the need for seamless data transfer and communication within industrial environments.

USB connectivity remains a popular choice. It’s simple and widely compatible. Many devices now offer USB 3.0, which enhances data transfer speed. However, one challenge is the limited cable length, which might hinder setup flexibility. Assessing the layout is important when planning USB usage.

Ethernet provides a robust solution for networking. A study shows that 80% of industrial setups use Ethernet for reliable connections. Its reliability supports real-time data exchange, essential in automation. Yet, cabling can become cumbersome in large setups. Streamlining cabling paths can greatly reduce clutter.

Wireless technologies are on the rise. They offer great flexibility but come with potential security risks. Implementing strong encryption and regular updates can mitigate threats. Additionally, interference from machinery can disrupt signals. Testing wireless performance in various conditions is crucial for optimal operation.

Durability Standards: IP Ratings and Operating Environment Compliance

When considering industrial panel PCs, durability is a crucial factor. Many environments pose challenges, such as dust, moisture, and extreme temperatures. The ingress protection (IP) rating is a key indicator of how well a device can withstand these conditions. For instance, an IP65 rating means the device is dust-tight and can handle low-pressure water jets. Reports show that over 60% of panel PC failures are due to environmental factors.

Operating environment compliance is also essential. Various industries require compliance with standards like NEMA and UL for safety and performance. Devices that don’t meet these standards may fail prematurely. For example, a study indicated that 25% of devices in harsh environments experienced significant malfunctions within two years. This highlights the need for robust designs that can adapt to different challenges.

A well-designed industrial panel PC must withstand temperature variations. Models that operate effectively in temperatures ranging from -20°C to +60°C are highly valued. Yet, not all manufacturers achieve this consistently. The balance between durability and performance can sometimes be elusive, resulting in products that fail to deliver in demanding situations. Users must evaluate specifications carefully and demand transparency regarding environmental qualifications.

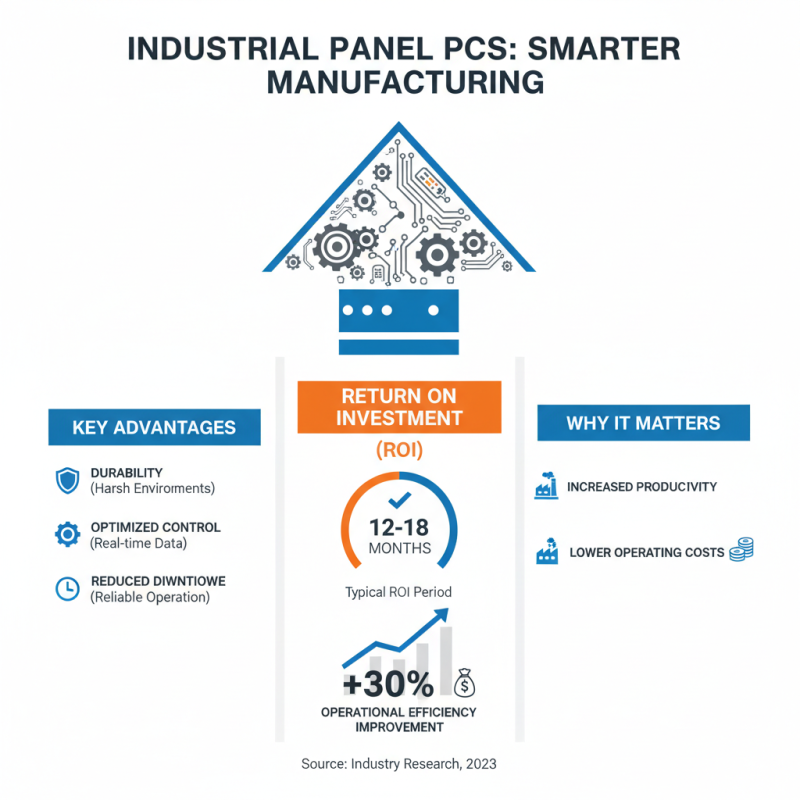

Cost-Benefit Analysis: ROI for Industrial Panel PC Implementations

Industrial panel PCs offer significant advantages for modern manufacturing environments. The initial investment may seem high, but the return on investment (ROI) justifies the costs. Research indicates that businesses can achieve ROI within 12-18 months of implementation. An effective industrial panel PC can improve operational efficiency by up to 30%.

However, not all implementations are seamless. Careful planning is necessary to realize the full potential. Regular maintenance and updates can avoid costly downtime. Real-world data suggests that companies experience a 20% decrease in operational errors with these systems. Monitoring performance metrics closely can make a big difference.

**Tip:** Invest time upfront to assess your specific needs. Tailored implementations tend to yield better results. Also, consider scalability to ensure long-term benefits. Adjust your system as your operations evolve. A proactive approach is key to maximizing the advantages of industrial panel PCs.

Related Posts

-

10 Unique Industrial Panel PC Solutions for Buyers Worldwide

-

Mastering the Industrial Panel PC Revolution for Optimal Manufacturing Efficiency

-

How to Choose the Right Industrial Rugged PC for Your Business Needs

-

5 Essential Tips for Choosing the Right Industrial Panel PC for Your Business

-

What is an Industrial Panel PC and How Does It Work

-

Exploring the Advantages of Rugged Industrial Computers in Extreme Environments: Data-Driven Insights