10 Essential Tips for Choosing the Right Industrial Computer System for Your Business

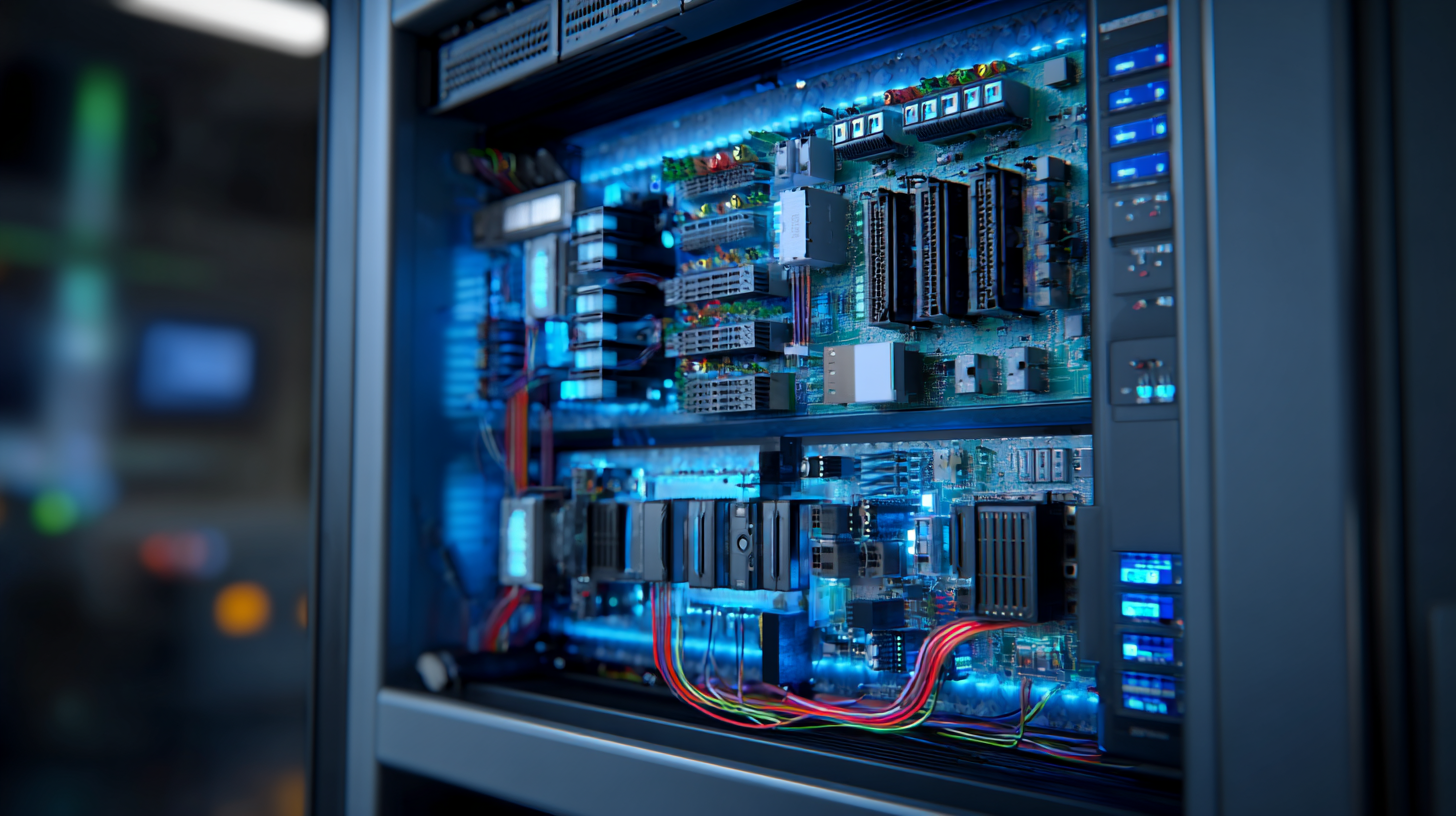

In today's rapidly evolving technological landscape, selecting the appropriate industrial computer system is crucial for optimizing operational efficiency and ensuring robust performance in industrial environments. According to a recent report by MarketsandMarkets, the global industrial computer market is projected to reach USD 8.3 billion by 2025, growing at a CAGR of 5.4%. This surge underscores the increasing reliance on specialized computing solutions to meet the demands of automation, data processing, and real-time monitoring. As businesses strive to enhance productivity and maintain a competitive edge, understanding the key factors that contribute to the selection of an industrial computer system becomes essential. From processing power to durability and scalability, the right choice can significantly impact both short-term success and long-term viability in today's industrial sector.

Key Considerations for Defining Your Industrial Computer System Requirements

When selecting an industrial computer system, defining your requirements is crucial to ensure optimal performance in your business environment. Start by assessing the specific applications your system will handle. For instance, if your operations rely heavily on data from sensors such as temperature, humidity, or pressure sensors, ensure your system can support the necessary input/output (I/O) interfaces and processing capabilities. This foundational step can significantly impact the overall efficiency and reliability of your system.

Another essential tip is to consider the environmental conditions where the computer will be deployed. Industrial settings can vary greatly, with factors such as dust, moisture, and temperature fluctuations playing a significant role. Ensure that the hardware you choose is ruggedized and rated for the specific conditions it will face. This not only enhances durability but also prolongs the lifespan of your equipment, ultimately reducing maintenance costs and downtime. Adapting your industrial computer system to suit your operational environment and technology requirements allows for greater scalability and adaptability in a rapidly evolving market.

Assessing the Performance Needs of Your Business Application

When selecting an industrial computer system, assessing the performance needs of your business application is crucial. According to a report by MarketsandMarkets, the global industrial PC market is expected to reach $4.87 billion by 2026, underscoring the increasing reliance on robust computing solutions in industrial environments. Understanding your application's workload will help you gauge the necessary processing power, memory requirements, and I/O capabilities essential for optimal performance.

Tip 1: Start by analyzing the specific tasks your applications will perform. For instance, manufacturing systems may require real-time data processing and high-speed connectivity, while monitoring applications might prioritize reliability and longevity. Evaluating these factors will inform your decision regarding CPU selection, as powerful processors like Intel’s Xeon series provide the performance needed for intensive calculations.

Tip 2: Consider the operating conditions in which your industrial PC will function. A study by Grand View Research highlighted that ruggedized PCs are often required in environments exposed to extreme temperatures, vibrations, or dust. In such cases, selecting systems rated for industrial use with features like fanless designs or sealed enclosures can significantly enhance performance durability and minimize downtime.

Evaluating the Reliability and Durability of Industrial Computer Systems

When selecting an industrial computer system for your business, evaluating reliability and durability is crucial. According to a report by VDC Research, nearly 60% of industrial computer failures are due to environmental factors, such as temperature fluctuations, dust, and moisture. This highlights the importance of choosing systems that are designed to withstand harsh conditions. Look for products that comply with industry standards such as IP65 or IP67, ensuring they are resistant to dust and water ingress.

Furthermore, the longevity of industrial computers can significantly impact operational costs. Research from Industry Research highlights that systems with a minimum lifespan of seven years reduce total cost of ownership by approximately 30%. When assessing potential systems, consider those with robust thermal management solutions and high-quality components that meet stringent reliability metrics, such as MIL-STD-810. These features not only enhance performance but also ensure that your investment remains protected against unforeseen failures, ultimately supporting your business's efficiency and productivity.

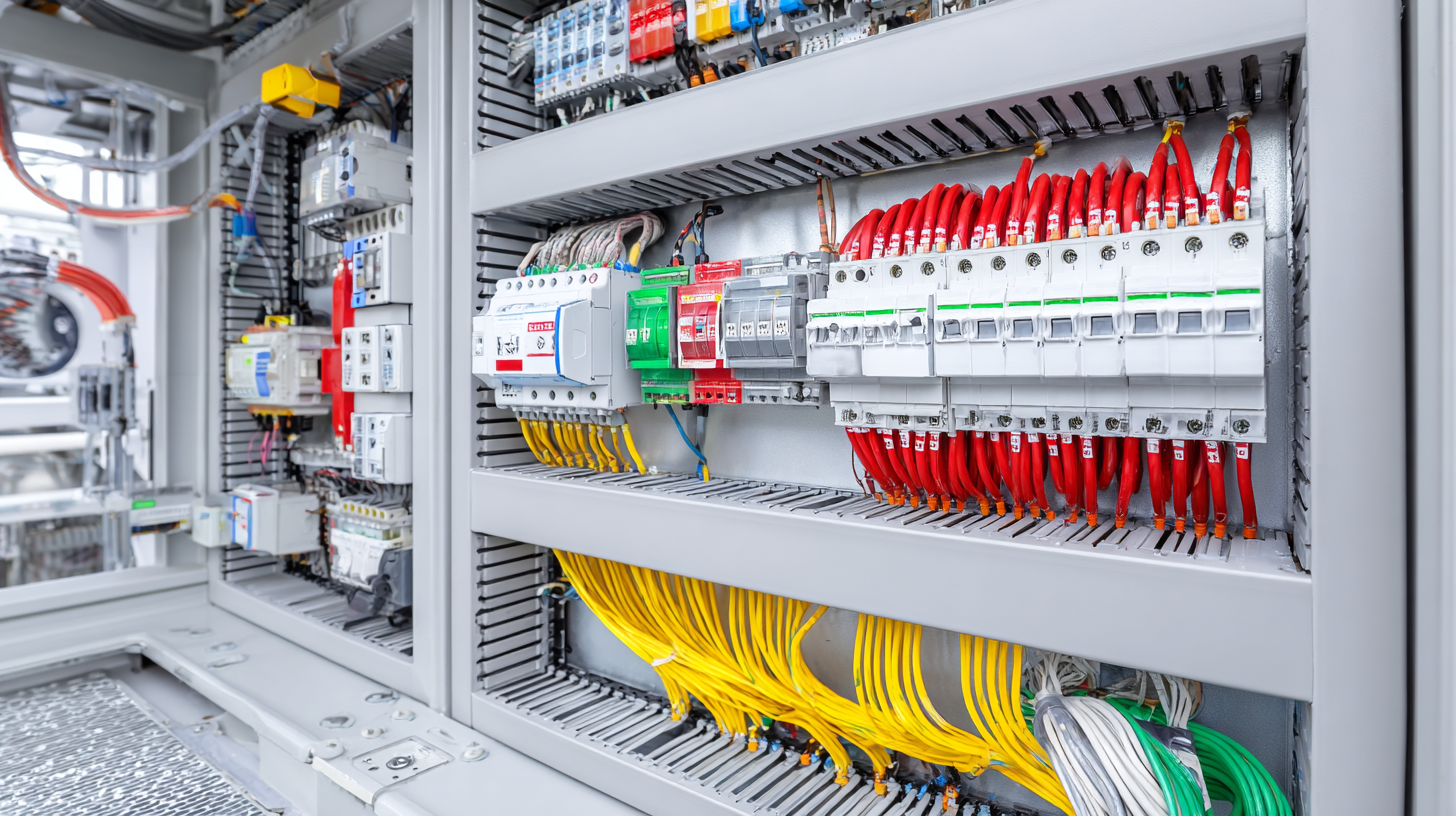

Understanding Connectivity Options for Industrial Computer Integration

When selecting an industrial computer system, understanding the connectivity options available is crucial for seamless integration into your existing infrastructure. Modern industrial environments require robust communication frameworks, making it essential to evaluate the types of interfaces and protocols supported by potential systems. Common connectivity options include Ethernet, USB, and Serial interfaces, facilitating reliable data transfer between devices and ensuring compatibility with legacy systems. It’s important to choose a computer that can easily interface with the equipment you already have, enhancing productivity and minimizing downtime.

Additionally, consider the scalability of connectivity options. As your business grows and technology evolves, your industrial computer system should support newer protocols while maintaining connections to existing equipment. Look for systems that offer flexible networking capabilities, such as wireless connections or support for IoT integrations, which can significantly expand your operational efficiency. A forward-thinking approach to connectivity will not only streamline processes within your facility but also prepare your business for future technological advancements, ensuring you stay competitive in the dynamic industrial landscape.

Connectivity Options for Industrial Computer Systems

Budgeting for Your Industrial Computer System: Costs and ROI Considerations

When considering an industrial computer system for your business, budgeting is a critical factor that requires thorough analysis. According to a report by Gartner, businesses can expect to allocate anywhere from 5% to 15% of their overall IT budget to industrial computing solutions. This range is influenced by various factors, including the scale of your operations and the complexity of the systems required. For example, if your business is involved in processes that demand high computational power and reliability, the initial investment may lean towards the higher end of this spectrum.

Furthermore, understanding the return on investment (ROI) associated with these systems is essential. A study by McKinsey suggests that companies that properly invest in industrial computing and automation can see productivity improvements of up to 30%. This not only justifies the initial expenditure but also potentially leads to significant cost savings over time. Additionally, investing in high-quality systems can enhance operational efficiency, reduce downtime, and lower maintenance costs, all of which contribute positively to the overall financial health of the company. Prioritizing your budget to accommodate a robust industrial computer system can lead to sustainable growth and enhanced competitive advantage in today’s fast-paced market.

10 Essential Tips for Choosing the Right Industrial Computer System for Your Business

| Criteria | Considerations | Estimated Costs (USD) | ROI Period (Months) |

|---|---|---|---|

| Processor Power | Choose based on application needs | $800 - $2,000 | 12 - 18 |

| Memory | Consider RAM size for multitasking | $200 - $600 | 6 - 12 |

| Storage | SSD vs HDD for speed | $150 - $500 | 8 - 14 |

| Operating System | Compatibility with existing software | $100 - $300 | 3 - 6 |

| Form Factor | Desktop vs Embedded systems | $500 - $1500 | 9 - 15 |

| Durability | Environment and usage conditions | $300 - $800 | 6 - 10 |

| Support and Warranty | Consider manufacturer support | $100 - $400 | 4 - 8 |

| Expandability | Future-proofing your tech | $200 - $500 | 5 - 12 |

| Connectivity Options | Need for network connections | $50 - $300 | 2 - 5 |

Related Posts

-

How to Optimize Your Industrial Computing Products for Maximum Efficiency

-

Essential Checklist for Selecting the Best Industrial Rugged PC for Your Needs

-

Innovative Uses of Rugged PCs Across Various Industries

-

Mastering the Industrial Panel PC Revolution for Optimal Manufacturing Efficiency

-

How to Choose the Right Industrial Rugged PC for Your Business Needs

-

5 Essential Tips for Choosing the Right Industrial Panel PC for Your Business