Top 10 Benefits of Using Industrial Panel PCs in Manufacturing Environments

In today’s fast-paced manufacturing environments, the integration of technology is paramount to maintaining competitiveness and efficiency. Among the technological advancements, the use of Industrial Panel PCs has emerged as a transformative solution. According to a recent market report by Industry Research, the global industrial PC market is projected to reach $5.4 billion by 2025, driven largely by the increasing automation and digitalization within industrial operations. This surge reflects the industry’s recognition of the potential that Industrial Panel PCs hold for enhancing operational productivity and ensuring seamless integration with existing systems.

Industrial Panel PCs are designed to withstand harsh environments while providing robust computing power, which is crucial for real-time data processing and visualization. Research indicates that manufacturers leveraging advanced computing solutions such as Industrial Panel PCs can achieve up to 30% improvement in operational efficiency and a significant reduction in downtime. These devices not only optimize workflow but also facilitate better data collection and analysis, empowering manufacturers to make informed decisions swiftly. As industry trends continue to evolve, the adoption of Industrial Panel PCs will undoubtedly play a critical role in driving innovation and operational excellence in manufacturing settings.

Benefits of Enhanced Durability and Longevity in Industrial Panel PCs

In manufacturing environments, the durability and longevity of equipment play a critical role in ensuring operational efficiency and minimizing downtime. Industrial panel PCs are specifically designed to withstand harsh conditions, including extreme temperatures, moisture, dust, and vibrations, which are often present on factory floors. According to a report by the Industrial PC market analysis in 2021, the adoption of rugged industrial PCs can lead to a 30% reduction in maintenance costs due to fewer breakdowns and repairs. Their robust construction is not only cost-effective but also supports continuous operation, enabling manufacturers to maximize productivity.

Moreover, enhanced durability also extends the lifespan of industrial panel PCs, often exceeding 10 years of operational capability compared to standard commercial computers, which typically last between 3 to 5 years. The increased longevity reduces the frequency of replacements, which is especially beneficial for manufacturing entities looking to optimize their capital expenditures. A study published by the International Society of Automation highlighted that investing in durable technology can yield a return on investment (ROI) of up to 50% through improved reliability and lower lifecycle costs. As manufacturers continue to embrace automation and smart technology, the implementation of industrial panel PCs with enhanced durability is essential for maintaining a competitive advantage in the industry.

Top 10 Benefits of Using Industrial Panel PCs in Manufacturing Environments

This bar chart illustrates the top 10 benefits of using industrial panel PCs in manufacturing environments. Each benefit is scored based on its impact and importance, showcasing why these devices are essential in modern industrial settings.

Increased Efficiency and Productivity through Real-Time Data Processing

In manufacturing environments, the integration of industrial panel PCs significantly enhances efficiency and productivity by enabling real-time data processing. These robust systems provide operators with immediate access to vital information, allowing for quick decision-making and streamlined workflows. With the ability to monitor machinery and processes in real-time, manufacturers can identify issues before they escalate, minimizing downtime and optimizing resource allocation.

Furthermore, industrial panel PCs can seamlessly connect with IoT devices and other smart technologies. This connectivity facilitates the collection and analysis of data from various stages of production, enabling manufacturers to refine their operations continuously. By leveraging real-time insights, businesses can adapt to changing demands more swiftly, implement predictive maintenance strategies, and enhance overall operational effectiveness. This not only increases productivity but also fosters a culture of continuous improvement within manufacturing facilities.

Improved User Interface and Experience for Operators in Manufacturing

The manufacturing landscape is increasingly adopting technology that enhances efficiency and productivity, and industrial panel PCs stand at the forefront of this transformation. By providing a user-friendly interface, these panel PCs significantly improve the overall experience for operators on the shop floor. According to industry reports, over 70% of operators indicate that a streamlined user interface reduces the time spent on machine setup and operation, leading to a marked increase in overall productivity.

Furthermore, modern industrial panel PCs incorporate touch-screen capabilities and intuitive software that cater specifically to operator needs. Research by the Smart Manufacturing Leadership Coalition reveals that companies utilizing advanced touch-interface technologies have seen a 15% decrease in operational errors due to improved user interaction. This not only enhances safety but also fosters a more engaging and efficient working environment where operators feel more in control and less overwhelmed by complex systems.

The ergonomic design of industrial panel PCs also plays a crucial role in user experience. Studies show that when operators work with systems designed for comfort and accessibility, they report higher job satisfaction and lower fatigue levels. An impressive 60% of manufacturing personnel express that ergonomic improvements directly correlate with their ability to perform tasks effectively, further emphasizing the importance of investing in user-centric technologies like industrial panel PCs in today’s manufacturing settings.

Top 10 Benefits of Using Industrial Panel PCs in Manufacturing Environments

| Benefit | Description | Impact |

|---|---|---|

| Improved User Interface | Intuitive touch screen interfaces enhance operator interaction. | Increased efficiency and reduced training time. |

| Durability | Designed to withstand harsh industrial environments. | Lower maintenance costs and longer lifespan. |

| Space Efficiency | Compact design saves valuable floor space. | Allows for more flexible factory layout. |

| Real-time Monitoring | Allows continuous tracking of production metrics. | Improves decision-making capabilities. |

| Integration Capabilities | Seamless connectivity with other systems and devices. | Enhances overall system performance. |

| User-Friendly Software | Software solutions tailored for manufacturing processes. | Improves operator productivity. |

| Enhanced Data Collection | Efficient gathering of operational data. | Facilitates data analysis for better outcomes. |

| Remote Access | Allows operators to access systems remotely. | Increases flexibility and responsiveness. |

| Energy Efficiency | Optimized power consumption for lower operating costs. | Contributes to sustainability goals. |

| Scalability | Easily expandable to meet growing operational needs. | Supports future growth without major overhauls. |

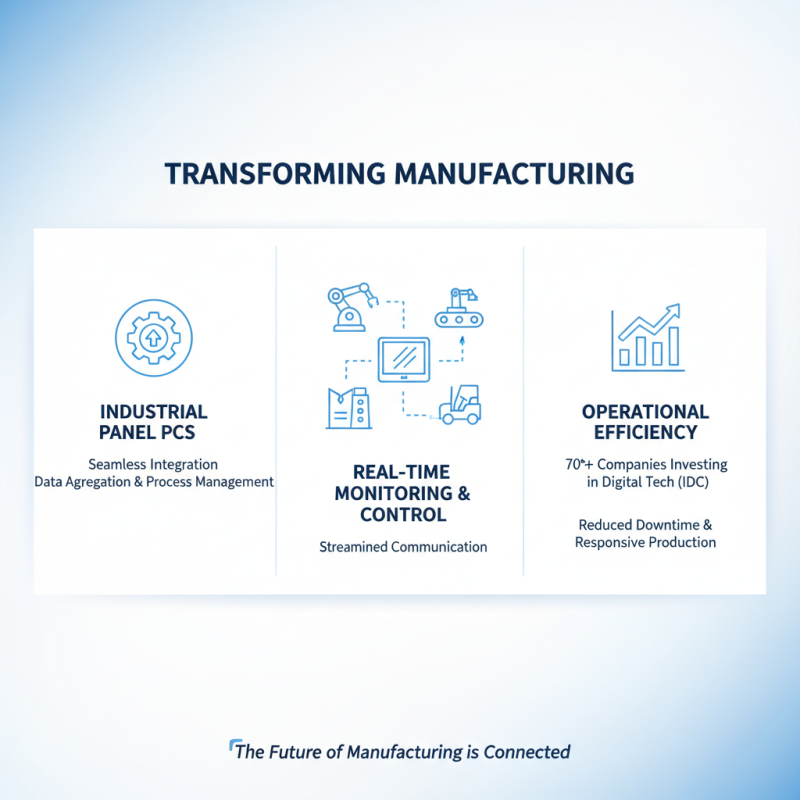

Seamless Integration with Existing Manufacturing Systems and Machinery

The seamless integration of industrial panel PCs with existing manufacturing systems and machinery is transforming the landscape of manufacturing environments. According to a report by the International Data Corporation (IDC), over 70% of manufacturing companies are investing in digital technologies to enhance operational efficiency. Industrial panel PCs serve as pivotal points for data aggregation and process management, allowing for real-time monitoring and control of various machinery setups. By functioning as a central hub, these systems streamline communication between machines, software applications, and personnel, reducing operational downtime and ensuring a more responsive production line.

Furthermore, industrial panel PCs facilitate the adoption of Industry 4.0 principles, enabling the interconnection of devices through the Internet of Things (IoT). As noted in a recent study by McKinsey, organizations that fully embrace IoT technologies can achieve a 30% reduction in manufacturing costs and a 10% increase in production efficiency. By utilizing industrial panel PCs, manufacturers can transmute existing equipment into smart machinery, linking legacy systems with advanced analytics and data visualization tools. This adaptability not only empowers manufacturers to optimize processes but also ensures longevity and relevance in an increasingly competitive market.

Cost-Effectiveness and ROI Considerations of Industrial Panel PC Usage

In the modern manufacturing landscape, the integration of industrial panel PCs presents significant cost-effectiveness and return on investment (ROI) advantages. By consolidating multiple functions into a single device, these versatile systems reduce the expenses associated with operating and maintaining separate components. The streamlined approach not only lessens hardware costs but also minimizes energy consumption, resulting in lower utility bills. Additionally, the robust design of industrial panel PCs ensures longevity and durability, reducing the frequency and costs related to hardware replacement and repairs.

Moreover, the enhanced productivity enabled by industrial panel PCs contributes to a substantial ROI. These systems allow for real-time data analysis and monitoring, enabling manufacturers to streamline processes and respond quickly to issues as they arise. Immediate access to information improves decision-making, which can lead to increased operational efficiency. By decreasing downtime and optimizing workflow, manufacturers can achieve higher output levels, translating directly into increased profitability. Investing in industrial panel PCs ultimately creates a sustainable financial model that can adapt to the ever-evolving demands of the manufacturing sector.

Related Posts

-

Mastering the Industrial Panel PC Revolution for Optimal Manufacturing Efficiency

-

10 Unique Industrial Panel PC Solutions for Buyers Worldwide

-

5 Essential Tips for Choosing the Right Industrial Panel PC for Your Business

-

Ultimate Guide to Choosing the Right Rugged Panel PC for Your Business Needs

-

10 Essential Reasons Why Your Business Needs an Industrial Rugged PC Today

-

Top 10 Tips for Choosing the Best Industrial Panel PC for Your Business